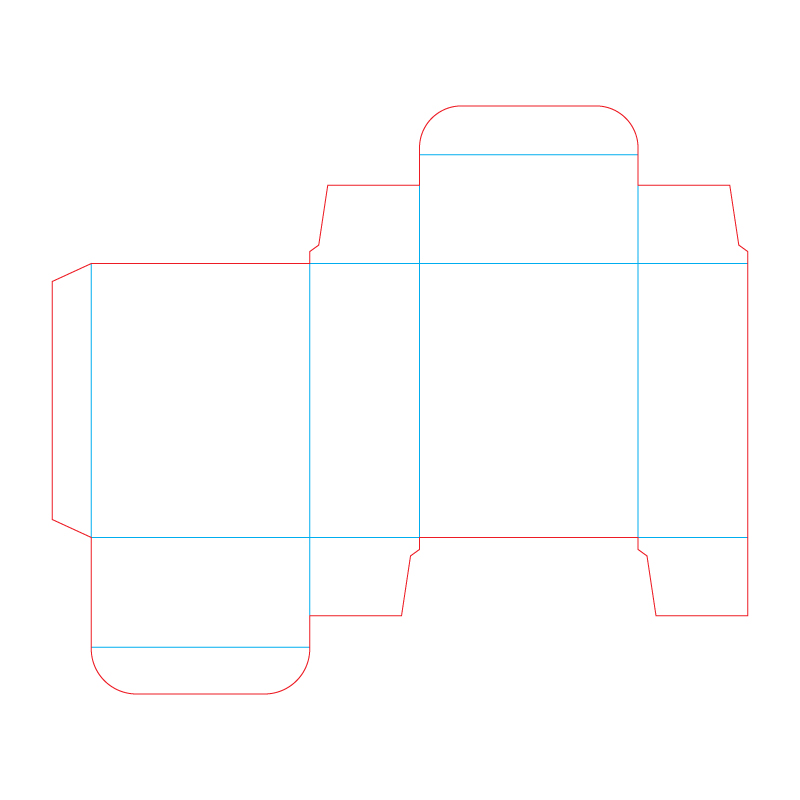

Reverse Tuck End Boxes

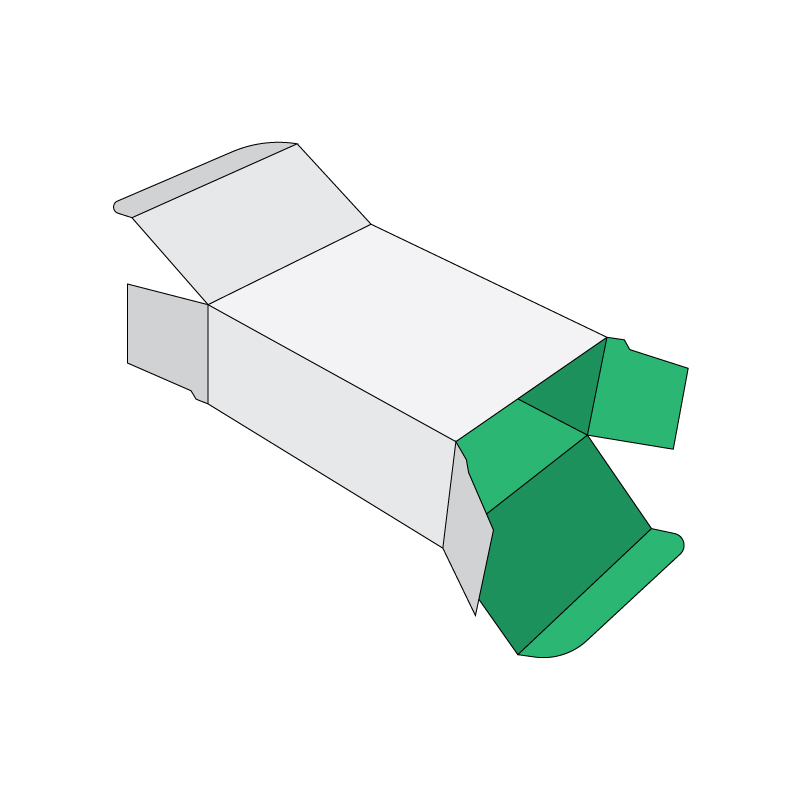

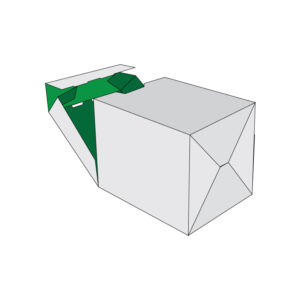

Reverse Tuck End Boxes are also known as RTE and are perfect for machine filling or manual filling of the product in the box. There are two tucks in the structure of the box one is at the bottom and the other one is at the top. The bottom tuck closes the back of the box, whereas the top tuck closes the front of the box. Ibex Packaging can manufacture custom RTE boxes for their clients according to the personalized specifications and tailored needs of the clients. Our boxes are made of strong and sturdy material where the bottom closure tucks the backside of the box to the front side. The top lock closure has friction so that the box can be easily opened or closed. The bottom of the box has a slit and tuck bottom, making the box more secure for the product. The boxes are made of rigid cardboard so that they are not disengaged due to the weight of the product. These boxes can be assembled by both hands as well as by the machines. RTE boxes are the simplest yet most functional boxes and can be used in a number of different industries.

Structure and Composition of Reverse Tuck End Boxes

There are two closure panels at the top of the box which swings in the opposite direction with the bottom folding in the front and the top panel folding in the rear of the box. In most of the cases, these reverse tucks end boxes are used in the food, beverage, cosmetics, and pharmaceutical industries. These boxes are self-locking boxes and don’t require any glue or tape to seal the box. These boxes are used by retailers and wholesalers as inner packaging boxes and in order to ship the product, these boxes are packed in another carton which acts as an outer container. We can ship these boxes in flat form because they are very easy to set up and assemble.

Specify your requirements and get a Custom Reverse Tuck End Boxes

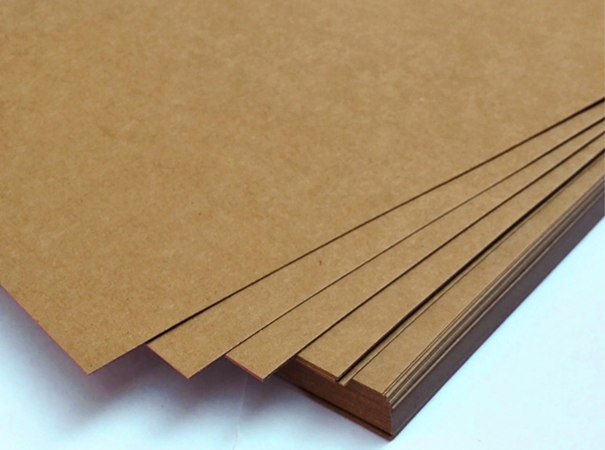

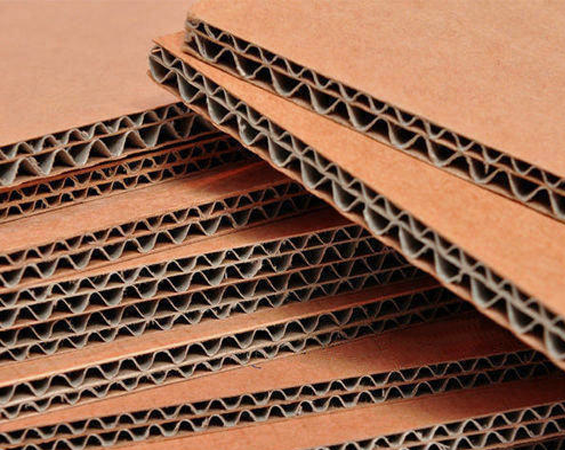

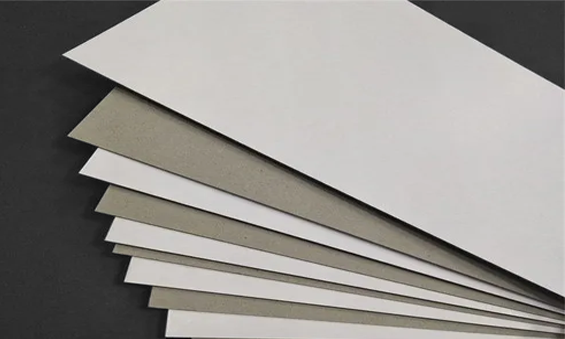

IBEX Packaging provides you reverse tuck end boxes in all the sizes, shapes, and dimensions. You can also select the paperboard of your own choice ranging from 10pt to 28pt in the form of environmentally friendly Kraft paper and E-Flute paper or regular card stock. The coating can also be done according to the requirement of the customer such as gloss finish, matt, or spot UV coating of the surface of the box. There are a number of default processes supported by such as die-cutting, gluing, scoring, and perforation of the boxes. You can also avail other options such as craving a custom window cut out, gold and silver foiling, branding by pasting the emblem and logo of your brand on the box.

Emily Robinson –

Our reverse tuck end boxes were tremendous and of high quality. I loved how the customer support executives of IBEX Packaging dealt with my order. I look forward to giving new orders with IBEX Packaging.